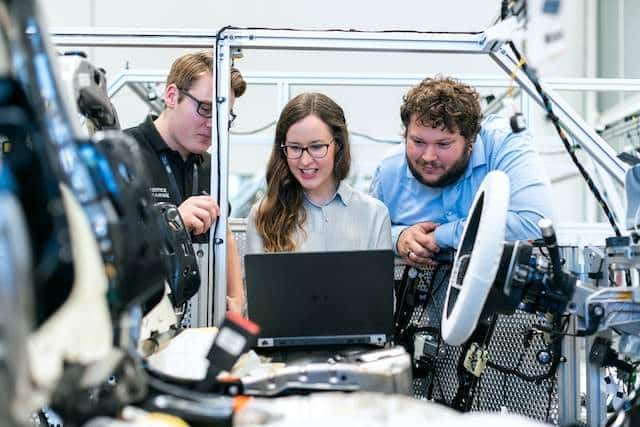

As an engineer, understanding the inner workings of industrial machinery is essential to design and maintain efficient systems. From large factories to small workshops, industrial machinery plays a crucial role in our modern world. However, with so many different types of components involved, it can be overwhelming to keep track of each one’s function and importance.

That’s why we’re here today – to break down the key components of industrial machinery and highlight what engineers need to know about them. So whether you’re a beginner just starting in your engineering career or a seasoned professional looking for a refresher, this blog post will provide valuable insights on how these components work together to keep machines running smoothly.

Precision Gears with No Backlash

One crucial component of industrial machinery that engineers need to be familiar with is precision gears. These are mechanical components used to transmit torque and motion between two connected shafts. In simpler terms, gears allow the transfer of power from one part of a machine to another, enabling it to perform specific tasks. Gears come in various shapes and sizes, each designed to meet specific needs.

However, one critical factor engineers must consider when choosing gears is the amount of backlash it has. Backlash refers to the amount of free movement between two connected gears. It can cause imprecision in movements, leading to errors or poor performance from the machinery. To address this issue, precision gears with no baclash have been developed. These gears have minimal or no clearance between them, ensuring precise and consistent motion transfer. This feature makes them ideal for applications that require high accuracy and repeatability, such as CNC machines and robotics.

Understanding the different components

Industrial machinery is a complex system composed of multiple parts, each with its unique function. Understanding the different components of industrial machinery, such as motors, gears, and bearings, is crucial to ensure that the machine operates efficiently and effectively. Motors serve as the power source, while gears are responsible for transmitting power and torque.

Bearings, on the other hand, reduce friction between moving parts, preventing premature wear and damage. A deep understanding of these components is essential to make informed decisions about maintenance, repair, and replacement. By understanding the role each component plays in industrial machinery, you can maximize the machine’s productivity and lifespan.

Importance of proper maintenance

Proper maintenance and replacement of components are crucial for achieving efficient functioning in any given system. Whether it’s a car, a computer, a refrigerator, or any other machinery, regular care is necessary to ensure peak performance. These components operate under specific conditions, and over time, their effectiveness can decrease.

As a result, the system’s efficiency is impacted, leading to higher energy consumption, reduced productivity, and even safety hazards. By regularly checking and repairing or replacing worn-out components, you can extend the life of your machinery, save money, and improve overall performance. Neglecting maintenance and replacement can lead to higher costs in the long run, so it’s essential to prioritize this aspect of care.

Tips for choosing the right components

When it comes to choosing the right components for your industry’s needs and requirements, there are a few key tips to keep in mind. First and foremost, it’s important to have a clear understanding of what your industry’s specific needs and requirements are. This will help you identify which components will be most effective in meeting your goals and addressing any issues or challenges that you may be facing. Additionally, it’s important to take into account factors like compatibility, reliability, and cost when making your decision.

You want to choose components that will work seamlessly with your existing systems and processes, while also being reliable enough to deliver consistent results. At the same time, you need to balance these factors with cost considerations to ensure that you’re getting the best value for your investment. By keeping these tips in mind, you can make an informed decision when choosing components for your industry that will help you succeed in today’s fast-paced business environment.

Common issues

As industrial machinery components become more complex, it’s only natural that issues may arise from time to time. However, these issues can often be resolved through systematic troubleshooting. One common issue that many people encounter is leaky hydraulic systems. This can lead to problems such as reduced component performance or even complete equipment failure.

By thoroughly inspecting the system, identifying any leaks, and replacing any damaged or worn-out components, you can often resolve the issue and restore the full functionality of your machinery. Additionally, you may encounter issues with electrical systems or mechanical components. Regardless of the type of issue, the key is to remain vigilant and take proactive steps to identify and address any problems before they become major headaches.

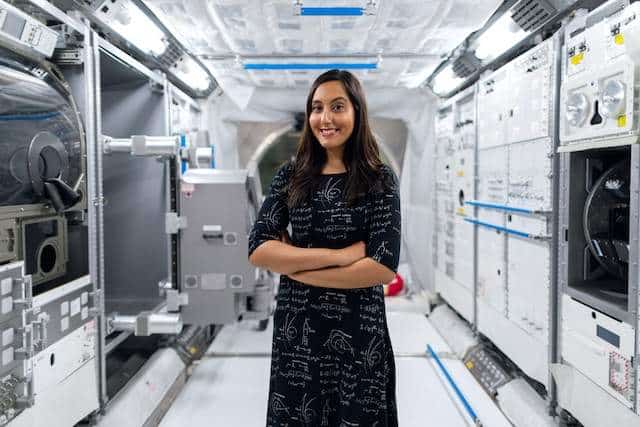

Innovations in industrial machinery components

With innovations in machinery components, the industry is seeing an increase in efficiency and cost-effectiveness. These new advancements are revolutionizing the way factories and manufacturing plants operate, helping them boost productivity, save time, and reduce operational costs.

From smarter sensors to advanced material coatings, every area of industrial machinery is seeing its fair share of improvements. By embracing these changes to the industry, companies are now able to take their production methods to the next level, while delivering better quality products at a more affordable price.

The impact of technology on the future

The world of industrial machinery components is evolving at an unprecedented pace, fueled by advancements in technology. From automated inspection systems to smart sensors and data analytics, the impact of technology on this sector is significant and far-reaching. With the ability to monitor machinery performance in real-time, detect potential faults before they occur, and even optimize production processes through artificial intelligence, the future looks promising for manufacturers and businesses.

However, this also means that companies need to adapt to stay ahead of the competition and leverage the latest technology to remain relevant. Only those who can keep up with the evolving landscape and embrace innovation will be able to thrive in the future.